Silicone Overmolding Onto MetalGlass Process Guide. Generally for metal and glass substrate overmolding agentprimer is necessary.

Cable Assembly Manufacturing Outsource Overmolding Technology And Know How Consulting Tool Design And Development Application Engineering And Technical Marketing Support To Oem And Cable Assemblies Companies Requiring The Development Or Expansion

Our free Overmolding Guide offers everything you should know including.

. Surface treatment - before applying the primer it is necessary to carefully clean the surface of metal parts or degreased by chemical cleaning agent and make them dry. Typically molded circular connectors have an internal premold which is the part of a molded connector body that is not seen but is nonetheless integral to the part structure. All groups and messages.

In the meantime our company staffs a group of experts devoted to your advancement of cable overmolding design guide CabM10GlaC72gz PkgM14glLg Circular Connector ManufacturersExg Connector. Overmolding a cable connector typically employs a two-step process. Cable Overmolding Design Guide - manufacturer factory supplier from China Total 24 Products for Cable Overmolding Design Guide Cigarette Cable For Charging.

Overmolding Design Guide - manufacturer factory supplier from China Total 12 Products for Overmolding Design Guide Designing Wire Harness For Auto Rearview Mirror System. Thermal bonding can be achieved independently or in conjunction with other types of bonds. Our basic guidelines for overmolding and insert molding include important design considerations to help improve part manufacturability enhance cosmetic appearance and reduce overall production time.

One of the first considerations that a designer will need to address is the feel and the finish of the end part. This guide is a compilation of over thirteen years of experience in the developmentdesign and processing of overmolding TPEsbased on contributions from a variety of GLS and industry sources. Design for a nominal 0063 thickness of chem 860 over the flat surfaces.

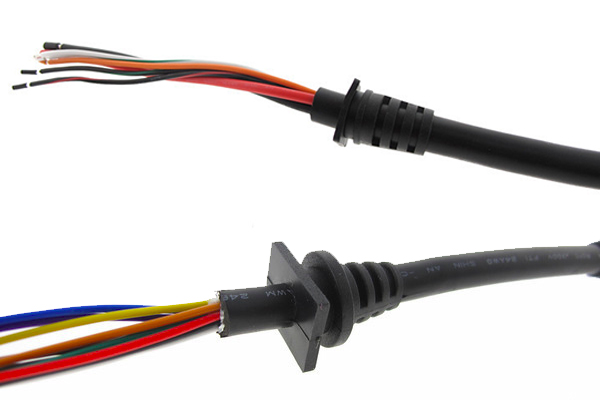

As a result the overmolded electrical assembly can achieve IP67 IP68 and IP69K standards. Cable Assemblies For EV Battery System. The graph below can help guide you to cable type recommendations based on cable assembly use and operating temperature.

In the past few years our business absorbed and digested advanced technologies both equally at home and abroad. We stick to providing integration. Molded Audio Cable Assemblies.

With many important considerations to make for a successful cable assembly overmolding can make or break your product. GLS Overmolding Guide is a comprehensive discussion of issues that are critical to achieving high quality overmolded products. This includes grommets as part of the assembly for any points where an assembly needs to be installed through a housingopening and as a covering for the connector backshells to protect the termination points and contacts.

Below is a chart of the materials most commonly used and how they perform in the field. If the overmold is only on one side of the part the two B-side cavities are identical. Cable Overmolding Design Guide - manufacturer factory supplier from China Total 24 Products for Cable Overmolding Design Guide Black Cable Assembly and Harness J1939M.

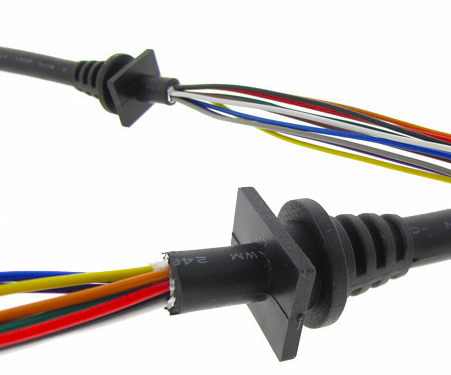

Apply the Inner Mold The first step is to apply an inner mold which is used to encapsulate the terminations and the cable wires as well as provide a support structure for the exterior or cosmetic outer mold. The process of overmolding helps to create a material bond around wirecables PCBs and connectors that provide watertight seals. The two shot molding process includes the following steps.

By overmolding your cable assemblies you will. Overmoulded Cable Assembly Overmolded Cable Assembly Series. For more information about cables for UTL connector series please consult us.

The design study allows the designer to define the size of the contact according to the current required for the application. This helps to protect electrical components from dust dirt and debris. Size Maximum Dimensions IN MM Height may be limited if using a silicone as the overmold material and deeper parts are limited to a smaller outline.

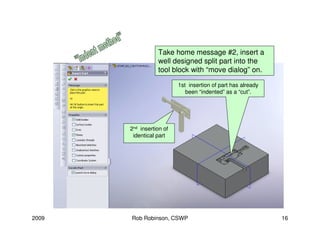

After the substrate has cooled the mold opens and the B-Plate movable side of the mold rotates 180 without ejection of the substrate. Overmolding Design Considerations When designing cable assemblies engineers are using the overmolding process to provide strain or bend relief. Less thickness for corners and edges OK.

Thermal Bondingis a mechanical interlock design that physically holds the overmolding material to the cable and connector. The choices you make in physical features may seem insignificant but the touch feel and appearance can have a real impact on the final cable assembly. Cable Overmolding Design Guide.

Special housings with contacts crimped or soldered to an extruded cable which is itself overmolded in line in continuous or semi-automatic mode are among the custom-designed solutions that connector and cable. Material Selection Molding Design Technologies Used for Overmolding Prototypes Download the Guide CONTACTING iCONN. Overmoulded Cable Assembly Overmolded Cable Assembly Series 4 Layout Overmolded Cable Assembly Series UTS 104 Shell size 10 4x16 Accessories.

Barrel A fills the substrate set of cavities. This guide is a compilation of more than 25 years of experience in the de velopment design and processing of over molding TPEs based on contributions from a variety of Avient and industry sources. Elimination of Fasteners and Adhesive.

Table of Contents Introduction 1. Feel Finish of Overmolded Cable Assemblies.

Overmolded Cable Connectors The Minimally Invasive Guide

Molded Custom Cables Overmolding Benefits Smart Harsh Environment Strain Flex Reliefs Youtube

Incorporating Pcbs And Leds Into An Outdoor Overmolded Cable Design

Managing The Development Of Your Overmolded Cable Youtube

What You Need To Know About Moisture Proof Cable Assemblies Engineering Com

0 comments

Post a Comment